Green Power Plants Algae: Renewable Raw Material of the Future

Away from fossil fuels, towards renewable raw materials for energy supply. This is the direction for the transformation of the energy sector and that is the goal of the energy transition, to which various regulations are attached in the EU and Germany. One of them states that at least ten percent of the energy used in transport should come from renewable energies by 2020. These are primarily the biofuels biodiesel, bioethanol and biogas. Whereby “bio” in this context means that the raw materials for the fuels come from renewable, biological material, i.e. from biomass. Rapeseed is turned into oil, which in turn becomes biodiesel. Grain and sugar beet become bioethanol and then petrol. The problem here is that huge areas of arable land are needed to grow rapeseed or grain for biofuel production. However, this land would not be sufficient to meet demand and would no longer be available for other types of cultivation on the same area. In the search for alternatives, algae represent a potent source of hope that has been researched in greater detail since the 1970s.

Multi-talent Microalgae

They are green, blue-green, yellow or brown, microscopically small or large and wobbly-glibby. Algae have many faces, but above all they are almost infinitely adaptable, flexible, tough and rich in nutrients. Microalgae have long played an important role in the economy: as binders and stabilisers, they ensure the necessary cohesion of all ingredients – this applies to yoghurt and cream cheese as well as to toothpaste and many other everyday products.

Whether for paints or cosmetics, fashion, lifestyle or architecture: pilot projects with algae are underway in many areas. The Algae House in Hamburg is one of them. Integrated into the façade are photobioreactors*, 3D algae farms that serve both as an insulating layer and as a source of hot water for the house. In addition, the microalgae cultivated in them can be extracted and sold for further use. There has also been an attempt in Paris to use algae facades to both purify water and generate energy. The algae clarify wastewater and rainwater and bind unwanted impurities in the biomass*. Since the process does not require chemicals, the clarified water can be used as grey water* for flushing toilets, for example. These approaches could be an important step in the circular economy of buildings. But the prototypes have not yet caught on.

Algae research: Juliane Wolf makes algae grow

The possibilities for using algae as a renewable resource for the circular economy and as an alternative to plastics and fossil fuels seem enormous. But according to scientists and engineers worldwide, research is only just beginning. The full potential of algae in industrial use has yet to unfold.

So what do algae have that other raw materials do not? What makes them so special and what can algae do that other raw materials cannot? What contribution can algae make to an economy that wants and has to become independent of fossil fuels?

Juliane Wolf knows the answers. The 36-year-old scientist has devoted herself to algae research and works in Brisbane at „The University of Queensland“. Juliane is a biotechnologist, studied bioprocess engineering and molecular biotechnology and process engineering, first in Köthen, then in Münster. After her Master’s, she went to Australia to write her doctoral thesis. Her topic: How can the growth conditions of algae be efficiently optimised on a micro scale and how can these findings be transferred to the large scale?

Since then, Juliane has been managing an algae pilot plant and makes algae grow. GTogether with her robot, photobioreactors and her AI, she investigates in Brisbane how to bring together microalgae technologie with innovative, sustainable land management and water purification practices. The goal of her research is, to optimize water quality, soil biology, plant health and fertilizer efficiency. The results of her research with microalgae shall improve sustainability and rentability of agriculture, livestock farming, mining and municipal waste water treatment and guarantee the future of fresh water safety.

In conversation, Juliane Wolf takes us into the world of algae and reveals the secrets of the mini power plants microalgae.

Juliane, what are algae actually?

Algae are plant-like, single-celled organisms that mostly live in water, but can also be found on land. They are about 300 million years old and thus older than plants. So they are actually the ancestors of plants.

There are microalgae and macroalgae. The macroalgae are the ones you know from sushi. They have a proper structure, with cells that have certain tasks and then grow together. The microalgae, on the other hand, are single-celled organisms or only comparatively small clusters of cells. They only need to divide in order to grow and can therefore multiply very quickly.

Algae are world champions in growth.

That is their most important characteristic for industrial use. Plants do it much more slowly; they first have to build up a structural apparatus in order to stand on the ground. No other organism on earth combines the characteristics of algae: They use light as an energy source, they need sun and then carry out photosynthesis, so they filter CO2 from the environment and release oxygen, just like plants. And they use water with the ingredients it contains and convert it into organic molecules that they need for their growth. If the conditions are just right, they can multiply explosively, while the water in which they live gives them support or also gets them from A to B. If the conditions are not so optimal, they are adaptation champions, which is why they are found everywhere on earth.

What are algae made of?

Oil, proteins and carbohydrates are the main components. In addition, there are vitamins, minerals, trace elements and pigments. Algae contain a wide variety of organic substances that are formed under specific growth conditions. If you understand when which substance is formed, you can make use of this knowledge and grow interesting substances. The glibbery of macroalgae comes from the sugar molecules between the cell walls. They are gelatinous, like a gel, flexible to a certain extent, but still maintain their structure so that they do not fall apart. They are used for alginates, which we use everywhere, especially in wound care for dressings and compresses, but also in dentistry, food and cosmetics.

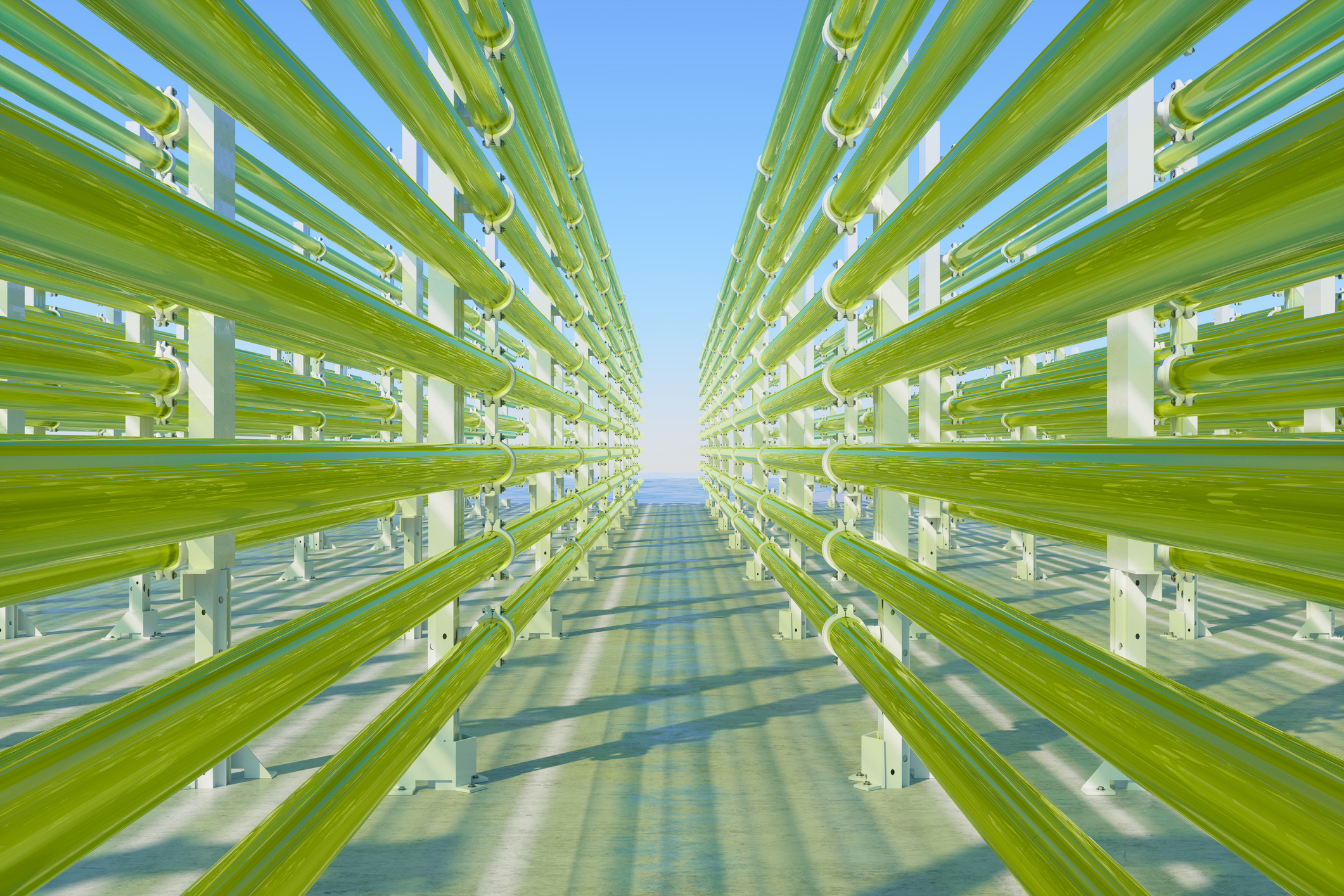

How are algae grown?

Algae need space. Be it in tubes lying above and next to each other, in horizontal tanks that can also be stacked on top of each other, or in vertical tanks that are then placed next to each other, like discs. In their respective environments, algae mainly need light in addition to water. The light supply should be high for many hours of the day. That is why large algae farms are often located in southern countries with plenty of natural light. In more northern regions, artificial light is also used. In addition, fertilisers such as nitrogen and phosphate are supplied via the water, supplemented with trace elements and sometimes a few vitamins. These are then optimal conditions for algae to grow quickly.

How is algae made usable?

Algae are cultivated and then separated from the water and broken down into their components. The oil is particularly valuable as an energy source for renewable energies. Under high pressure, the proteins and carbohydrates can also be converted into oil. However, this requires additional energy. In addition, unwanted by-products must be extracted in order not to reduce the quality of the fuel.

The energetically but also financially more favourable process would be to extract valuable ingredients, such as the proteins, beforehand and sell them, for example, as high-quality animal feed.

And what then is the secret recipe that makes algae so exciting for the industry?

Photosynthesis. And the unknown biodiversity.

That’s all?

Yes. You can’t do it with flowers or plants. With algae, anything goes. You can use them as an energy source and turn them into oil, or purify water, or use them as a resource for food, high-quality chemicals or even as a production platform for medicines and drugs.

Algae are small, relatively simple in structure and can divide and multiply very quickly. The basic building block is CO2 from the air instead of organic carbons such as sugar compounds or starch. They carry out photosynthesis and are mini power stations in terms of energy. That is actually the whole secret.

Oil for example. We can produce oil with algae, either as omega3 or as fuel, whatever. Oil is actually fat, as with humans, so it is actually a storage form of energy and it is normally produced when the nutrient balance is not optimal. And so you can sort of manipulate these solutions in which you cultivate the algae in such a way that they either only go for growth – in other words, promote cell division. Or if you go for oil, for example, then you let them starve. They then convert their carbohydrates into fat.

I think the question should rather be, not what makes it such a multi-functional object but: What prevents it from doing so?

OK, so: what’s stopping algae from becoming an absolute jack-of-all-trades?

The cost.

What costs?

If you imagine harvesting wheat from the field. There’s a tractor that harvests both, the whole plant – the total biomass – and does an initial separation by separating the wheat grains from the rest. This is a process that has been optimised for centuries and is now relatively cheap to carry out. The algae, on the other hand, must first be separated from the water. This process can be quite energy-intensive if you transfer it to a large scale, i.e. ten hectares or more, and don’t think of urban farming denkt. There are different methods: Filtering, flocculation, centrifugation or combinations of these methods. Whether the effort and the price are worth it depends on the market value of the desired algae product.

There has been a lot of progress in this area in recent years, and it is now possible to make it much simpler or much cheaper than 10 or 20 years ago. But it is still too expensive for algae as an energy source, yes. That refers to mass production on a large scale with raw material products that are supposed to be very cheap.

A biofuel from algae is currently not competitive with fossil crude oil or natural gas, which are simply extracted from the ground to the surface.

They are already produced and have only been stored under the earth’s surface for millions of years. Perhaps another interesting fact is that algae are also a basic building block of today’s crude oil.

But many hopes are pinned on algae as a substitute for crude oil?

Yes, and rightly so, but here we still have to do a lot of research and still have to find new ways. If you look at energy demand globally about 80 per cent of it is supplied in the form of fuels, i.e. primarily from fossil raw materials, while electricity, i.e. power, only contributes 20 per cent. Renewable energies today mainly contribute to the supply of electricity. And although the share of electricity in global energy demand is steadily increasing to replace the primarily fossil fuels in the energy mix, the problem of fuel has not yet been solved, not in any way. Cars, planes, ships, space ships need fuel. So does heavy industry for the production of steel and cement. They can’t function on electricity alone at the moment. Of course, there are solar-powered cars and things like that, but the weight of a battery versus the weight of a fuel is far from competitive.

How much algae can you harvest?

We produce in water and here, in Brisbane in the subtropics, we can produce an average of 25 grams of dry biomass per square metre per day. And we can cultivate all year round. In the temperate, European climate, this value is more like 15 grams.

What are the challenges in algae production?

One of them is certainly the optimal combination of nutrients. With plants, we know relatively well which predators there are and how to combat them. With algae, we just haven’t got that far yet. For example, I isolate microalgae from water bodies and then try to find out which combination of nutrients they like best.

Another is the lighting conditions. They have to be right and there are also different conditions for different types of algae.

How do you find the optimum for the algae?

I have developed a robot that pipettes the existing nutrient solutions together and I can test 1,800 combinations of nutrient media per strain within two weeks. This means that if a nutrient solution has 20 individual components, I can increase and decrease the concentrations and then test which ingredients interact with each other and how this affects the growth, positively or negatively…

… if growth is the goal. And what other goals are there, for example?

If you have other goals, where for example, proteins are the crucial component of the algae, you won’t necessarily look at growth. The question is then: In which nutrient combination is the protein combination best. Depending on the algae, the optimal nutrient combination can be very different. And then we test the light next. Because photosynthesis is extremely important and every algae likes different light intensities or day and night rhythms.

If the algae is doing well, it grows quickly and likes to divide, and if it is not doing so well, it does not.

So robots, AI, digital engineering and technologies play a crucial role?

Absolutely. Because algae grow so quickly, you have to react much faster. There is a lot of development in the field of sensor technology and automation. Everything you measure has to be interpreted, and there is still a lot to learn about what something means when I measure it. With the robot I achieve precision and I can measure day and night. At the moment, it measures every three hours – if I did it by hand, I would have to work many night shifts. We create an extremely large amount of data. Bottleneck is the data evaluation. Then I write software.

Means you have to be able to understand both, the biological standards as well as the software?

Exactly. I am the interface. Neither a pure biologist nor a crass engineer. Without the knowledge from both directions, it would be difficult to develop such high-throughput screenings. As a pure process engineer, it is impossible to understand the microbiological processes in detail. As a pure biologist, on the other hand, it is difficult to convert biological processes into technological-economic processes.

In order to understand the complex processes that go on in biology, these days you need knowledge of IT, software and, increasingly, programming skills, so a degree in engineering provides a very good basis.

An engineer who now assembles a bicycle or a car knows every part and then knows how it works. Whereas in biology we have a black box, an alga, or the cell or the plant, and we have an input that we put in, and then we measure some output. We then have to use theories to try to explain what actually happened in the cell. This can only be done with many measurements and data analysis on a large scale.

In order to keep up with the rapid pace of development in research, we are also extremely interdisciplinary in our small research team. Our small postdoc team consists of a biochemist, a molecular biologist, a mechanical engineer, a biotechnologist – that’s me – and our team leader, who comes from electron microscopy. This is not necessarily typical for small research teams, which are otherwise very subject-specific, but it has the advantage that we can also respond well to various requests from industry.

What are you most interested in researching that you haven’t found a solution for yet?

There is still a lot of research to be done. Just as with plants, new molecules or combinations of molecules are constantly being discovered that give rise to new applications.

But: There is a theoretical maximum how fast we could produce algae.

If you look at how much solar energy is available and how much of it an algae can absorb, you can calculate the photosynthetic efficiency that is theoretically possible.

But we can’t achieve that in practice.

<p”>And we don’t know why.</p”>

There are many mechanisms that play a role and are responsible for this. For example, if I want to supply light, which the algae need as a source of energy for growth, then the energy requirement also depends on how many processes are taking place in the algae at the same time that need energy. But too much light is also bad. You can think of it like a household with all kinds of electrical appliances, where the power demand can change dynamically from minute to minute depending on how the occupants are using it. So I need a precise measure of the criteria: how much light, in terms of intensity, when do I need which light, in terms of wavelengths. So this dependence on light is extremely difficult to understand. Because photosynthesis itself has extremely many adjusting screws.

Sounds like the idea of using algae for fuel and use them to replace fossil fuels is still a long way off?

They won’t replace it 100%, but it will be a component. There won’t be another era like the fossil fuel era. Where everything is designed around one resource. It has to be a mix in the future.

At the moment, algae are mainly in the market in those sectors where the products are still relatively expensive. So high value products like food supplements, natural colourings or preservatives. By cultivating algae with nutrients from wastewater, we could minimise environmental problems such as the contamination of our waters with nitrate and phosphorus. Depending on the type of wastewater, you have to see for which product the algae can be used. The intended use also depends very much on official regulations and restrictions, which were not originally developed for an efficient circular economy.

Juliane, I have learned a lot, thank you so much for the exciting and inspiring conversation and many greetings to Brisbane.

*Photobioreactor:

Compound word from ancient Greek phôs, English: light (e.g. also in phosphorus or photosynthesis) and bioreactor, a facility in which microorganisms such as algae, mosses, bacteria, or other small plants are cultivated outside their actual and natural environment. In a photobioreactor, those organisms are cultivated that use light for their own energy production and build up their own biomass with light and C02.

*Biomass:

Refers to the amount of organic matter that is available in usable form for energy production. But: The term is not clearly defined and is defined differently in biology and energy technology.

*Grey water:

Slightly polluted wastewater from showers, baths or washing machines that can be treated and then reused as service water for flushing toilets, watering the garden or for commercial purposes, among other things.

*Dry biomass:

This is the pure weight of the algae after they have been taken out of the water, without the weight of the water.

Algae Profile

There are more algae species than there are plant and animal species combined. Seaweed, brown algae, phytoplankton & Co: Estimates of how many algae species there are range from 30,000 to 1 million*, the most commonly read figure is 400,000. Only around 200 algae species are known in more detail and only a fraction of these are used industrially, e.g. as food and in food supplements, as biofuel and cosmetics, in medical products, water filters in house construction, in fashion and design. The algae that we can see in the water and that we also know as food (sushi, wakame, nori and many more) belong to the group of macroalgae. They are rich in nutrients, are considered a superfood, can grow up to 60 metres long and are usually found in salty seas, sometimes also in fresh water. In addition, there is the group of microalgae invisible to the naked eye, so called because they are microscopic. Microalgae are also used and cultivated for economic and industrial use. Chlorella and Spirulina are particularly well known in the food supplement sector, Nannochloropsis as an omega-3 supplier to the animal feed industry, or Haematococcus in the antioxidant and colourant sector in the food sector. For example, salmon, shellfish or flamingos are pink because they absorb a pigment (astaxanthin) via the food chain that comes from the algae.