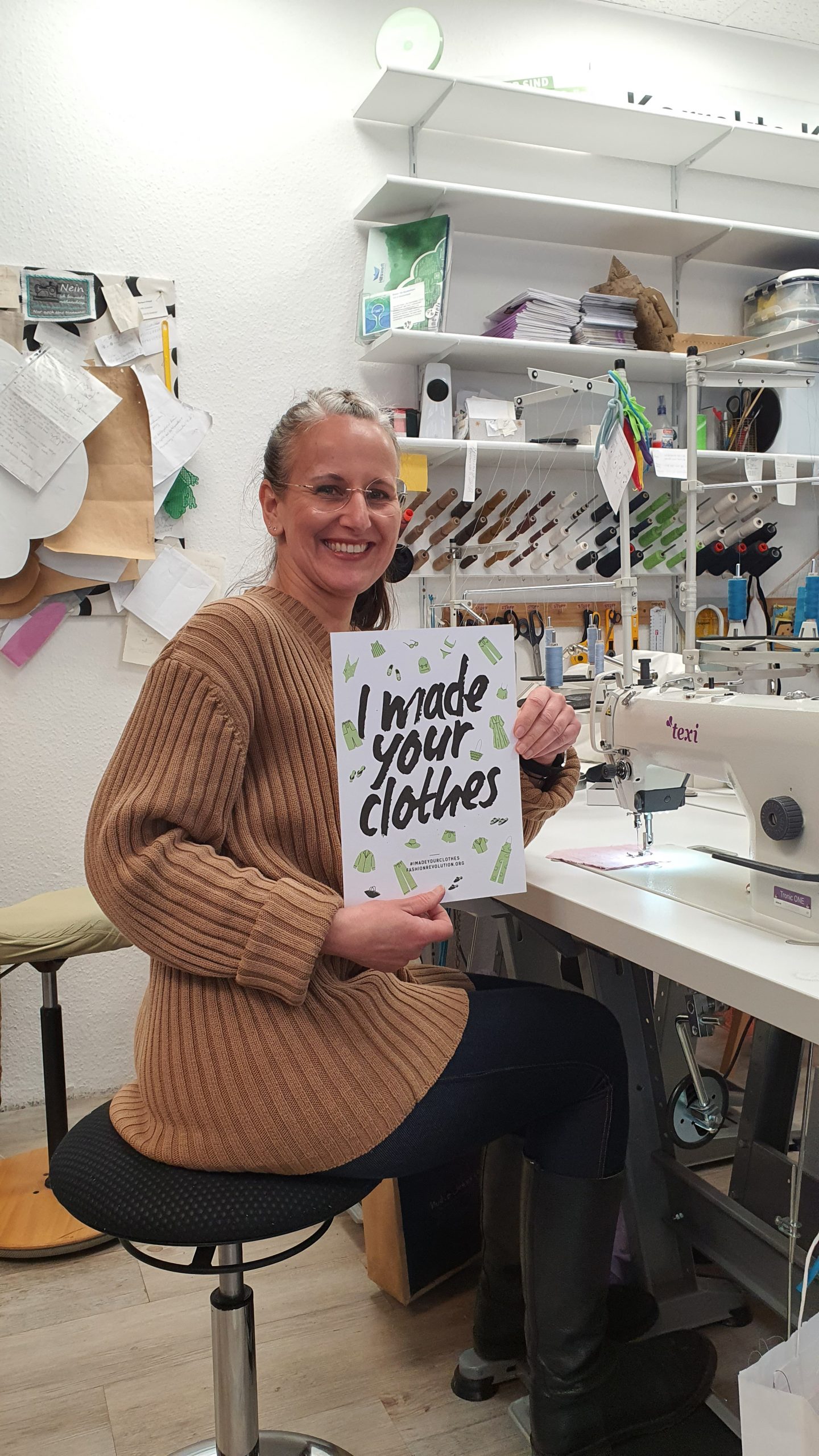

Almost Fair Fashion…: How Mandy Geddert uses elastic bands to make sustainable fashion even more sustainable

he eco-rubber band, like the entire fair fashion movement, is still literally in its infancy. Soon, however, it will be used in many industries and may eventually replace the conventional synthetic rubber band. The road here was hard, but now demand is high, says Mandy Geddert, who is finally enjoying success with her invention.

Fast fashion or fair fashion: In fashion, two business models face each other. They are fundamentally different. For fast fashion, several collections per year are produced under often inhumane working conditions, at the lowest possible cost from materials with a short lifespan. This is precisely the problem: textiles as mass-produced goods are often heavily polluted with chemicals and microplastics. They become throwaway fashion and damage the environment along the entire value chain. Firstly, through enormous resource consumption and the use of harmful substances in production. And finally, as residual waste, because the clothing is not recyclable.

Fair fashion – also called sustainable fashion, eco fashion, green fashion, ethical fashion, slow fashion – is the opposite. It is produced under ethical working conditions, environmentally friendly, from ecologically clean materials. The items are biodegradable or recycled. Fair fashion is a trend that is slowly but steadily gaining ground. For some years now, more and more consumers have been asking for these qualities and want to wear fairly and eco-produced fashion. Textile labels such as IVN Best, GOTS (Global Organic Textile Standard), Bluesign, Fair Wear Foundation, Green Button show which brands belong to fair fashion. But: For consumers, this is sometimes not much help. There are too many labels and they often only certify part of the materials, production and supply chains.

What is missing is a standard for all steps in the cycle of the textile industry. This is also a problem for fashion producers: if you really want to produce sustainable fashion, you need intermediate products that all equally meet the strict criteria of the different labels. But they don’t, Mandy Geddert found out. When she founded her sustainable children’s fashion label CHARLE Berlin in 2010, her vision of sustainable, beautiful children’s fashion almost failed. At CHARLE Berlin, the dresses, trousers, jumpers and jackets for children should be able to grow with them for at least three years. Elastic bands are a basic requirement for this. But they were also the biggest challenge.

In the interview, Mandy Geddert tells us why rubber bands have prevented real sustainable fashion so far and how she first turned the market for sustainable rubber bands around and then built it up.

Mandy, what role do elastic bands play in fashion and in your label CHARLE Berlin?

Hardly any garment can do without elastic bands. We just don’t see them most of the time, they are used in the cuffs of trousers, dresses, skirts, jackets and shirts, a lot in sports and outdoor clothing and in shoes like Chelsea boots. Without elastic bands, our clothes often wouldn’t fit and wouldn’t hold. And without elastic bands I would not have been able to offer any grow-along fashion for children.

At CHARLE Berlin, my aspiration was to create a beautiful design of ecological children’s clothing that grows with them, is durable and for which the concept of sustainability applies throughout the entire life cycle. This was not a problem at first with the materials, such as fabrics: they are sustainable and I source them from Germany, so I have local sourcing with short distances. But the challenge was to make clothes that grow with the child: I needed elastic for waistbands so that the skirts and trousers could keep up with the growth spurt of children over the age of three. In 2010, I could only get that from synthetic rubber. You can’t recycle mixed materials. And so I could not implement my understanding of sustainability.

So rubber is not always natural rubber?

Exactly. Rubber, including rubber bands, is made from natural rubber or synthetic rubber. The types of production, the manufacturing processes, have nothing to do with each other. Natural rubber is made from latex, the milk of the rubber tree. The tree is scratched and the milk is collected. Synthetic rubber is based on petroleum and is a chemically manufactured product. It is therefore difficult to degrade and it is not sustainable. But: the difference is usually not obvious through the language. It is rubber or caoutchouc and both terms are used synonymously for natural rubber and synthetic rubber. This leads to misunderstandings. And the problems of environmental impact are often not addressed because “rubber” is only used as a word for two varieties, for biologically produced rubber and for the synthetic version.For sustainable fashion, I need sustainable rubber bands and they are exclusively made of natural rubber. Surprisingly, they didn’t exist in 2010.

I then did some research and started looking for producers worldwide. In Japan, I got in touch with a manufacturer of conventional and organic ribbons with its own certificate. I had samples sent to me and tried to find out what was in the ribbons. This was not possible and the company did not give out any information. But it is part of my company’s philosophy to only work with partners who are transparent, where there are no reservations. I had the same problem with another manufacturer from Germany. Moreover, the quality was poor.

Then I thought to myself: OK. Then you do the pioneering work and make the ribbons yourself. There have been ribbons for so long, but synthetic ribbons can’t have been around that long, someone must have started with them. And anyone who makes synthetic ribbons can also make ribbons from natural rubber. From then on, I continued my research – and ran into closed doors for two years.

But you then founded CHARLE – PREMIUM HABERDASHERY and specialised in sustainable rubber bands. How did the turnaround and breakthrough come about?

I found a family business in Austria that produces elastic and non-elastic ribbons. At first, unfortunately, the owner was absolutely not interested in my idea. But I stayed on the ball. Conventional elastic bands are covered by synthetic yarns, be it crocheted, braided or woven. For my bands, exactly these two factors were to be different: they were to be made of natural rubber and sheathed in organic cotton. I got the yarn, that was no problem.

Why wasn’t the family business interested?

In the 1990s, we still had a successful textile industry in Germany, Austria and in some European countries in general. It was only in the 1990s that many companies moved their production to Asia because the material and production were cheaper there. This was a hard time for the family business. It had to remain competitive and specialise to do so. They then managed to stabilise the company – by setting high standards for their own quality and focusing on special belts. I could not promise any interesting production quantities with my natural rubber-biocotton rubber bands – and the boss did not want to take a risk and start an uncertain new production of rubber bands.

How did you manage to convince the company?

I was deeply convinced that the company and the team were exactly the right ones for my project. That’s why I was persistent and tried to convince the boss. I think I hit on an already existing belief in him: That it can work and you have to try. After almost a year, he agreed and we started production.

There was also headwind from other designers. My rubber bands made of natural rubber were about ten times more expensive than those made of synthetic rubber. This has changed with the increase in production quantities, but just a few years ago almost everything in fashion was about price.

At some point, the moment arrived. Christmas 2012 I held the first regenerative rubber band in my hands. Now, in 2021, we are a team of five people in Berlin and the team in Austria. We have more than 50 different bands in our range. We develop ribbons on customer request and offer small quantities. With this, we meet the nerve of young designers and start-ups who are committed to sustainable product development.

How is demand developing?

The ambition to produce completely sustainably and thus to be stricter than the seals is now shared by many producers. I work with Stephanie Devine from THE VERY GOOD BRA, the team behind DARIA DARIA, Sophie Pollack from WE BANDITS, with NATASCHA VON HIRSCHHAUSEN and Annett Borg from BESONNEN, to name but a few. And demand from areas outside of fashion is also increasing and we expect this trend to continue. Especially as our organic rubber bands have a longer life than conventional bands. The rubber bands are now also being used in shoe and product design, in the toy or automotive industry.We continue to research and would like to develop a material that is even more sustainable than our bands made of natural rubber and organic cotton already are.

Our vision is to replace synthetic bands with sustainable ones worldwide, and also to advance sustainable rubber cultivation. There is really still a lot to do here. We are fully committed to recyclable elastic and non-elastic bands.

You did pioneering work: What insight from the early days has shaped you the most?

It is difficult to sell quality on the German market. If you don’t produce in bulk and cheaply, you have a hard time competing on the conventional market.

Consumers rarely ask because they don’t know the seals or don’t understand the differences between the seals and the complexity of how they are awarded. You can’t blame anyone for that. If the care label of a shirt says 100% organic cotton, people assume that the yarn, the etiquettes and all other sewing ingredients are also organic. This is usually not true, but many people don’t know that.

This should and would change if the criteria for the seals were tighter.

When it comes to sustainability as an overall concept, most processes have not yet been thought through to the end. This starts with the framework conditions for the cultivation of organic cotton and its logistics, mostly from overseas, and goes on to the distribution of the products and their disposal. Acting in a globally organic and environmentally friendly way, everyone involved in the entire value chain all over the world, up to and including all of us as consumers – that is actually utopian. Nevertheless, I believe it is feasible.

Mandy, thank you very much for your power, persistence, all the insights and this interview.

Continue reading and choose your beautiful sustainable kid fashion item at CHARLE Berlin or visit the store of CHARLE premium haberdashery and look for your perfect eco-fair rubber band.